E-commerce Platform Stretch film Manufacturers

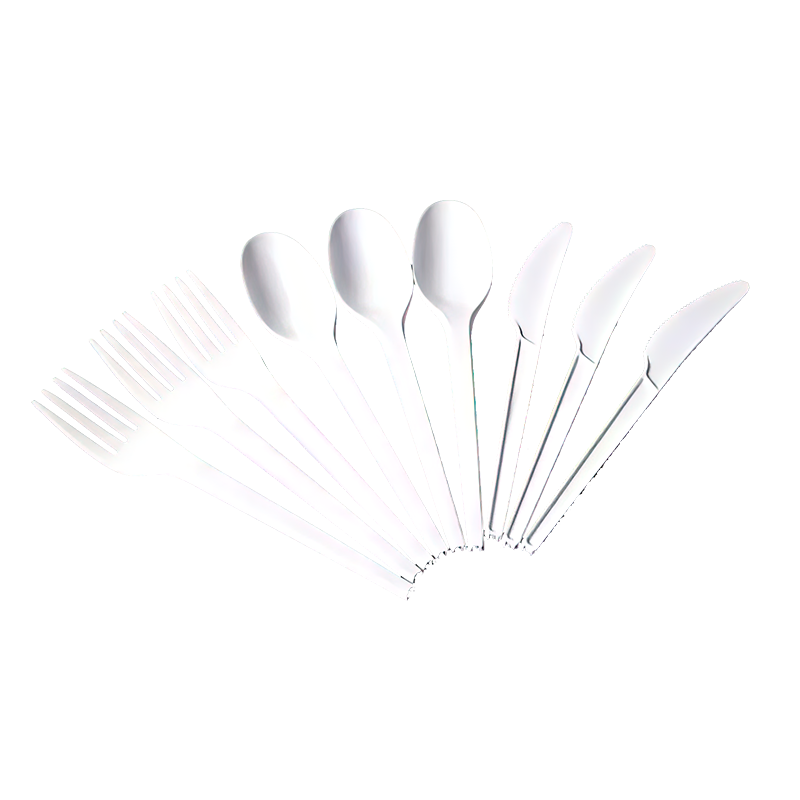

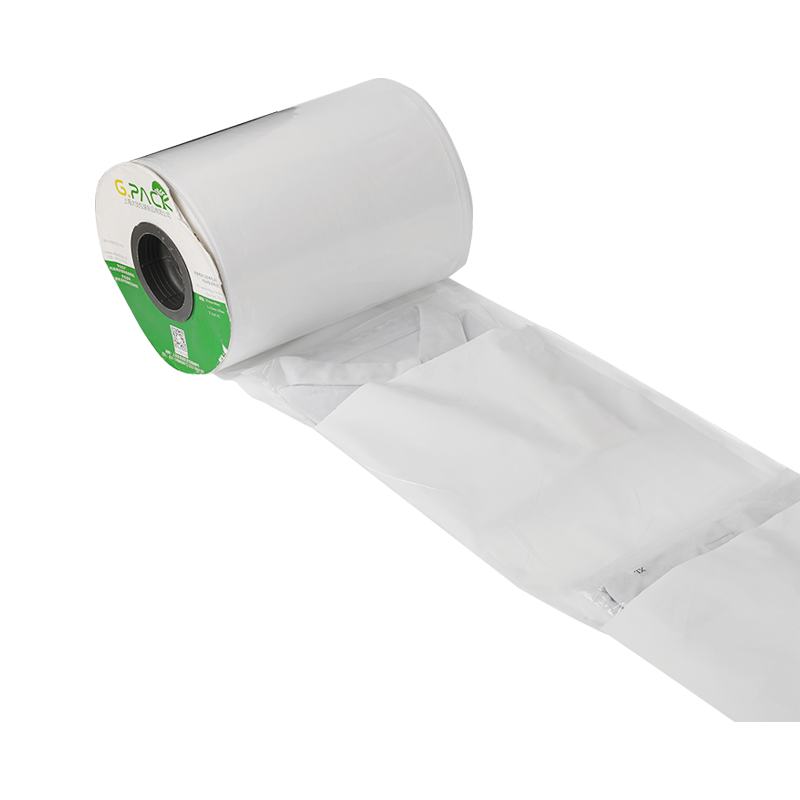

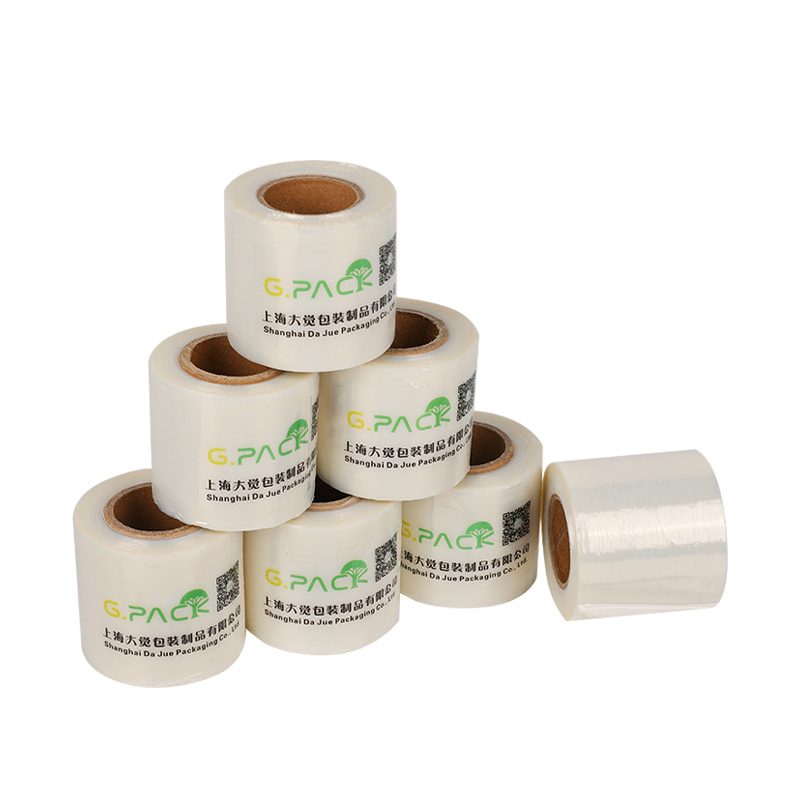

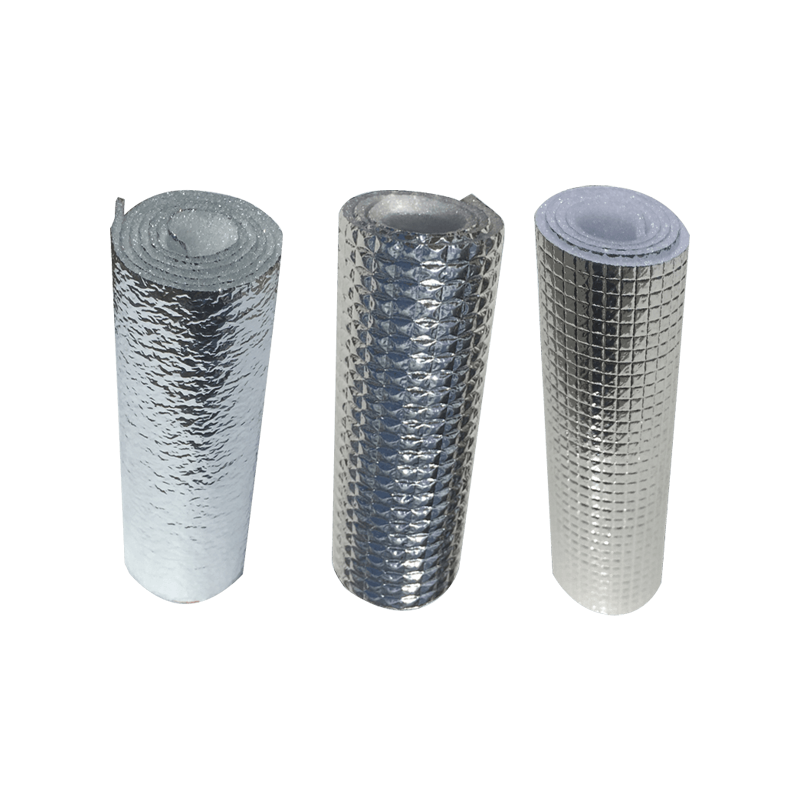

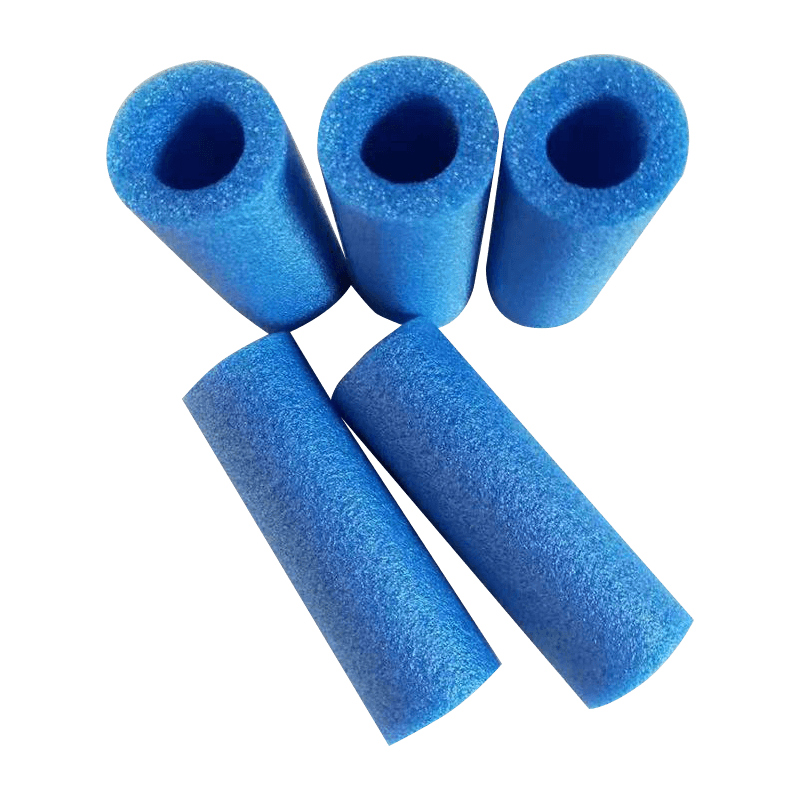

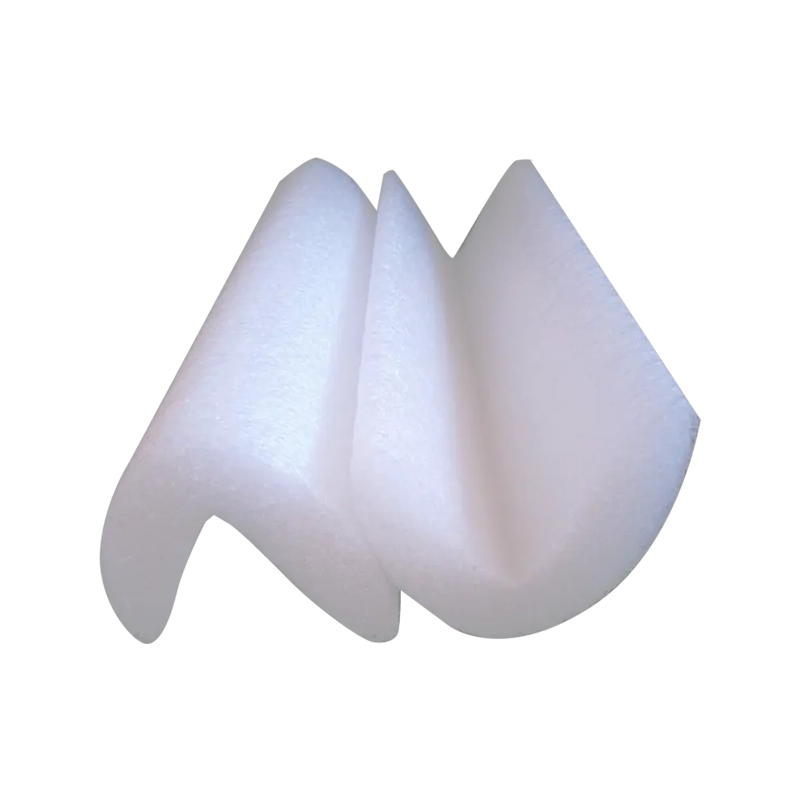

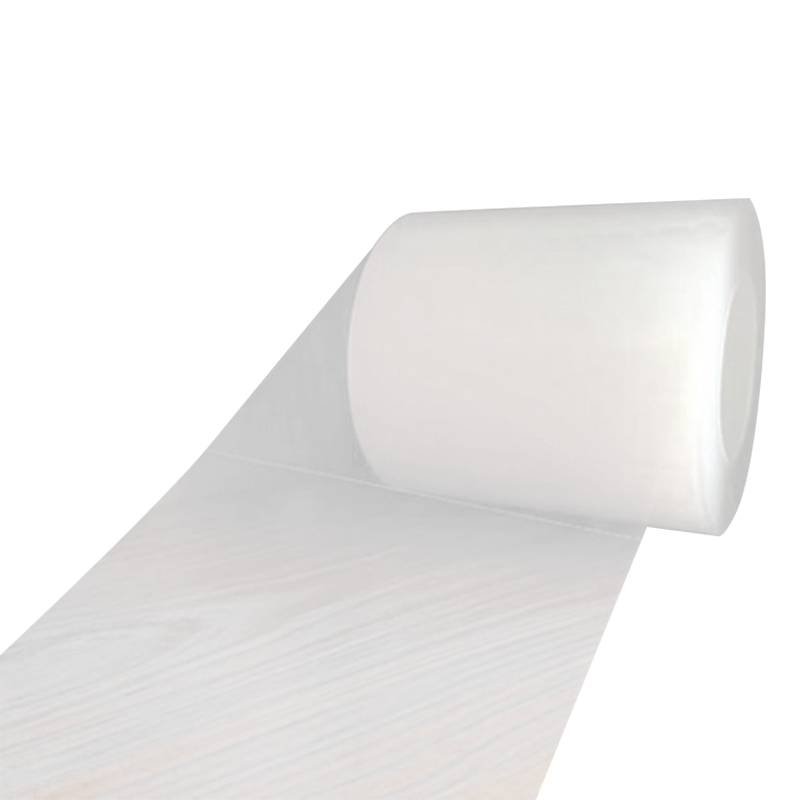

Our company can produce film series products, mainly including anti-static film, point-break film rolls, film sheets, film rolls, shrink film, etc. Product specifications and materials can be customized.

Product Category

Get in Touch With Us

Who Are We?

Dajue (Zhejiang) New Material Technology Co., Ltd.

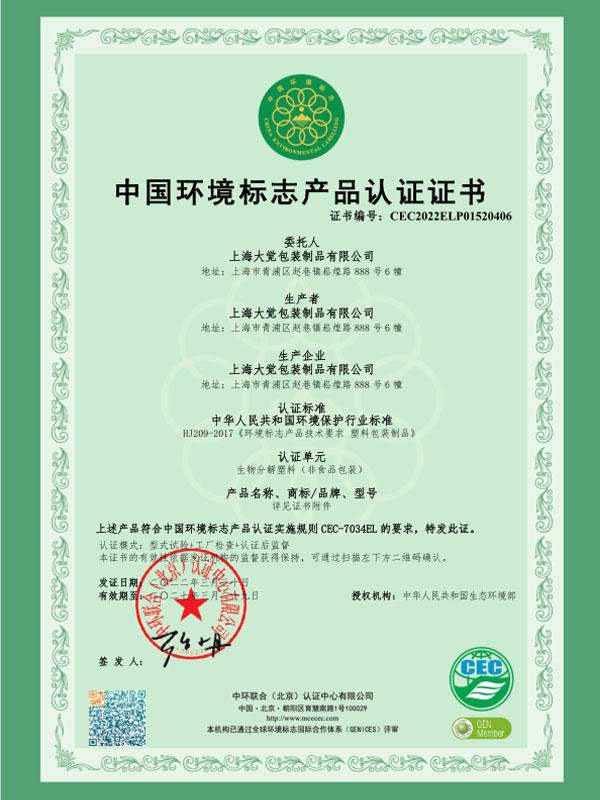

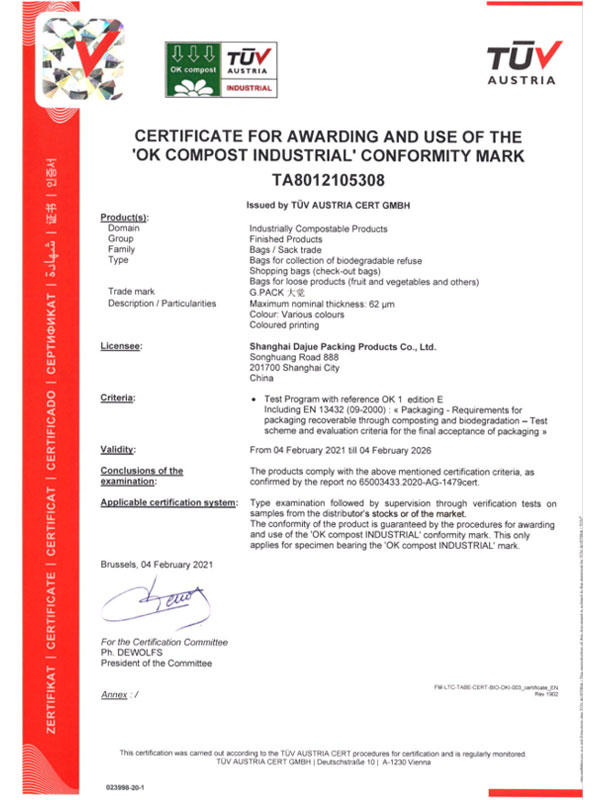

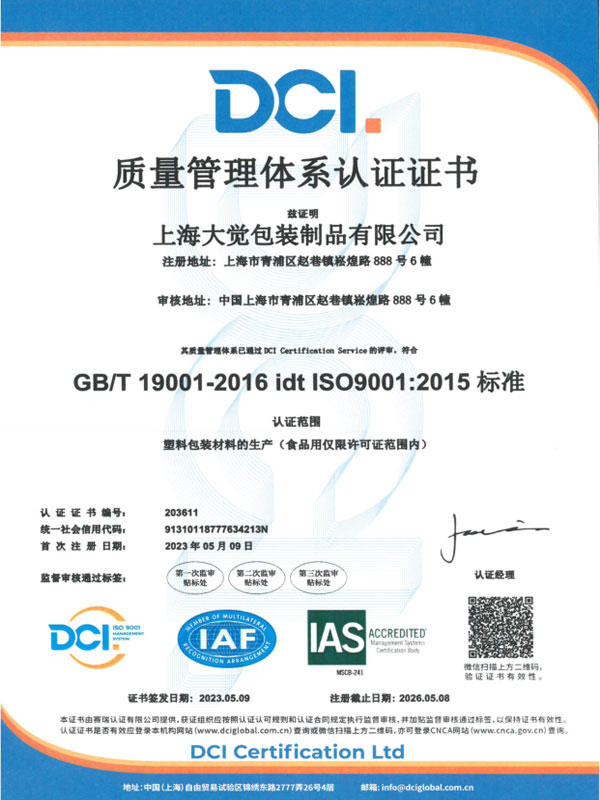

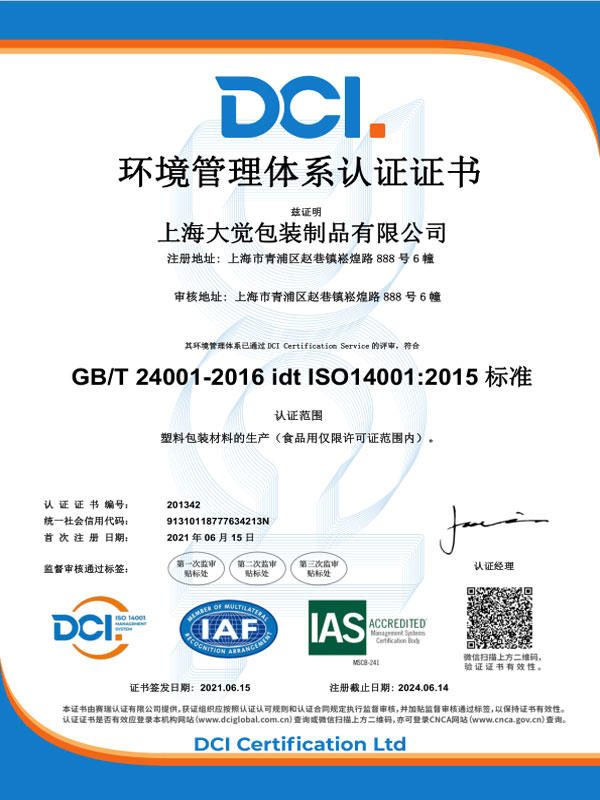

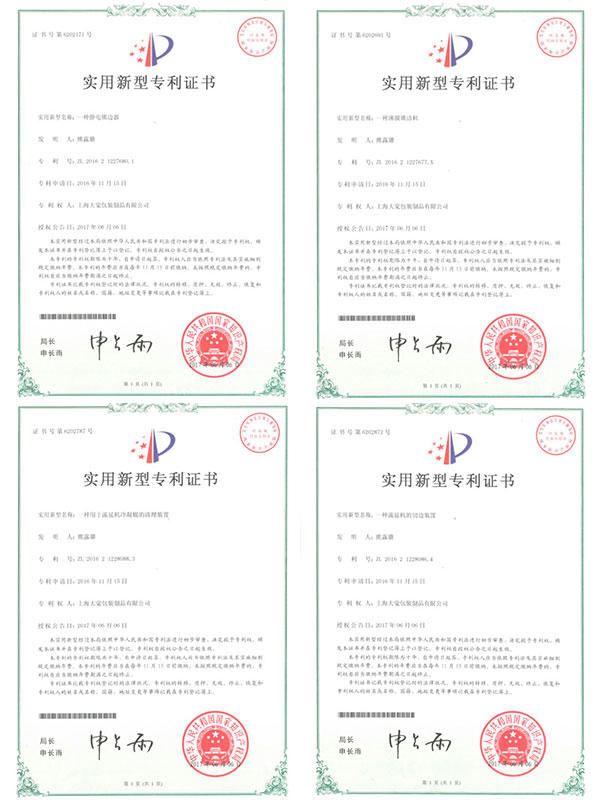

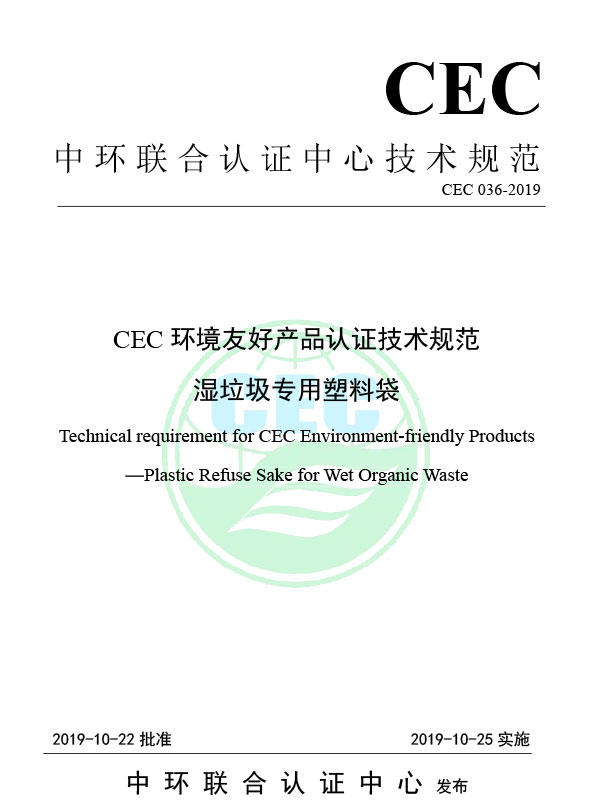

Founded in 2005, Shanghai Dajue Packaging Products Co., Ltd. is a high-tech enterprise mainly engaged in the research and development, production, and sales services of green and environmentally friendly new materials (products). It is committed to developing the research and application of biological/CO2 based materials.As China Wholesale E-commerce Platform Stretch film Manufacturers and E-commerce Platform Stretch film Factory.It has a headquarters base in Shanghai, a production base in Jiaxing, and a research and development base in Beijing. Currently, the company has the most advanced production and experimental testing equipment and facilities in China. It has 41 patents, including 3 invention patents and 1 design patent; participated in drafting more than 20 national, industry, and group standards.

Dajue will adhere to the development goal of green technology in the future, and in the context of "carbon peak, carbon neutral" and global plastic prohibition, commit to developing the research and application of biological/CO2 based materials. Relying on the continuous building of production capacity and research and development capabilities, through material application innovation, product innovation, business model innovation, combined with the integrated development of industry, university, and research, fully layout the application market of green and environmental protection new materials, It comprehensively focuses on industries such as biomedicine, automotive industry, agricultural and forestry materials, and daily consumer goods.

-

How do the production processes for biodegradable vacuum bags differ from those for traditional plastic bags?

Biodegradable vacuum bags have emerged as a promising alternative to traditional plastic bags. But how exactly do the production p...

-

What are the advantages of using PLAY material compared to other materials for a Biodegradable Breeding Basin?

Innovations in sustainable agriculture have led to the development of novel solutions aimed at minimizing environmental impact whi...

-

How should I dispose of biodegradable bamboo straws?

As environmental consciousness continues to grow, many individuals are opting for eco-friendly alternatives to traditional plastic...

-

Do biodegradable bags cost more than traditional plastic bags?

One of the pivotal debates in the packaging industry revolves around the cost of biodegradable bags compared to traditional plasti...

Film Industry knowledge

What are the advantages of anti-static film?

Anti-static film, also known as anti-static plastic film or ESD (Electrostatic Discharge) film, offers several advantages in various industrial and commercial applications where static electricity poses a risk or concern. Here are the key advantages of anti-static film:

Static Electricity Prevention: The primary advantage of anti-static film is its ability to mitigate and prevent the buildup of static electricity. Static electricity can damage sensitive electronic components, attract dust and contaminants, and pose safety hazards in certain environments.

Protection for Electronics: Anti-static film is commonly used for packaging and protecting electronic components, such as computer parts, semiconductors, and integrated circuits. It helps prevent electrostatic discharge (ESD) that could damage these sensitive devices during storage, handling, or shipping.

Dust and Contaminant Control: Anti-static film reduces the attraction of dust particles and contaminants to surfaces covered with the film. This is crucial in cleanroom environments, manufacturing processes, and industries where cleanliness and product quality are paramount.

Safety: In environments where static electricity can lead to safety risks, such as explosive or flammable atmospheres, anti-static film helps reduce the chances of sparks or ignitions that could lead to fires or explosions.

Improved Product Quality: When used in manufacturing and packaging, anti-static film ensures that finished products remain free from static-related defects, ensuring higher product quality and reducing scrap and rework.

Ease of Handling: Anti-static film can reduce the tendency of materials or products to stick together due to static charges, making handling and processing more efficient.

Extended Equipment Life: By preventing static discharge, anti-static film can prolong the life of sensitive equipment and machinery, reducing maintenance costs and downtime.

Versatility: Anti-static film comes in various forms, including bags, sheets, and rolls, making it suitable for a wide range of applications. It can be customized to fit specific requirements.

Environmental Benefits: Some anti-static films are designed to be environmentally friendly and may be recyclable or biodegradable.

Compliance with Industry Standards: In industries where ESD control is critical, the use of anti-static materials may be required to comply with industry standards and regulations, ensuring product integrity and safety.

Static-Sensitive Device Packaging: Anti-static film is commonly used to package and protect static-sensitive devices like hard drives, memory chips, and PCBs during shipping and storage.

Reduced Production Costs: By preventing ESD-related damage to components and products, anti-static film helps reduce production costs associated with defects and rework.

In summary, anti-static film plays a crucial role in preventing electrostatic discharge and its associated risks, making it an essential component in industries where static electricity control is vital for product quality, safety, and reliability. Its ability to protect electronic components, control contaminants, and improve overall efficiency makes it a valuable asset in various applications.

What material are most commonly used in shrink film?

Shrink film, also known as shrink wrap or shrink plastic, is commonly made from one of the following materials:

Polyolefin (Polyethylene or Polypropylene): Polyolefin is the most common material used for shrink film. It is available in two primary types:

Polyethylene (PE) Shrink Film: PE shrink film is often used for packaging food products, consumer goods, and industrial items. It is FDA-approved for direct contact with food and is available in various thicknesses and grades.

Polypropylene (PP) Shrink Film: PP shrink film is known for its clarity and high shrinkage rate. It is often used for packaging items with irregular shapes, such as cosmetics and promotional items.

PVC (Polyvinyl Chloride): PVC shrink film is durable and offers excellent clarity, making it suitable for retail packaging of products like CDs, DVDs, and gift baskets. However, it has become less popular in recent years due to environmental concerns related to chlorine content and recycling challenges.

PETG (Polyethylene Terephthalate Glycol-Modified): PETG shrink film is a clear, high-clarity material with good shrinkage properties. It is commonly used for retail packaging, including beverages, cosmetics, and consumer goods.

Anti-static film, also known as anti-static plastic film or ESD (Electrostatic Discharge) film, offers several advantages in various industrial and commercial applications where static electricity poses a risk or concern. Here are the key advantages of anti-static film:

Static Electricity Prevention: The primary advantage of anti-static film is its ability to mitigate and prevent the buildup of static electricity. Static electricity can damage sensitive electronic components, attract dust and contaminants, and pose safety hazards in certain environments.

Protection for Electronics: Anti-static film is commonly used for packaging and protecting electronic components, such as computer parts, semiconductors, and integrated circuits. It helps prevent electrostatic discharge (ESD) that could damage these sensitive devices during storage, handling, or shipping.

Dust and Contaminant Control: Anti-static film reduces the attraction of dust particles and contaminants to surfaces covered with the film. This is crucial in cleanroom environments, manufacturing processes, and industries where cleanliness and product quality are paramount.

Safety: In environments where static electricity can lead to safety risks, such as explosive or flammable atmospheres, anti-static film helps reduce the chances of sparks or ignitions that could lead to fires or explosions.

Improved Product Quality: When used in manufacturing and packaging, anti-static film ensures that finished products remain free from static-related defects, ensuring higher product quality and reducing scrap and rework.

Ease of Handling: Anti-static film can reduce the tendency of materials or products to stick together due to static charges, making handling and processing more efficient.

Extended Equipment Life: By preventing static discharge, anti-static film can prolong the life of sensitive equipment and machinery, reducing maintenance costs and downtime.

Versatility: Anti-static film comes in various forms, including bags, sheets, and rolls, making it suitable for a wide range of applications. It can be customized to fit specific requirements.

Environmental Benefits: Some anti-static films are designed to be environmentally friendly and may be recyclable or biodegradable.

Compliance with Industry Standards: In industries where ESD control is critical, the use of anti-static materials may be required to comply with industry standards and regulations, ensuring product integrity and safety.

Static-Sensitive Device Packaging: Anti-static film is commonly used to package and protect static-sensitive devices like hard drives, memory chips, and PCBs during shipping and storage.

Reduced Production Costs: By preventing ESD-related damage to components and products, anti-static film helps reduce production costs associated with defects and rework.

In summary, anti-static film plays a crucial role in preventing electrostatic discharge and its associated risks, making it an essential component in industries where static electricity control is vital for product quality, safety, and reliability. Its ability to protect electronic components, control contaminants, and improve overall efficiency makes it a valuable asset in various applications.

What material are most commonly used in shrink film?

Shrink film, also known as shrink wrap or shrink plastic, is commonly made from one of the following materials:

Polyolefin (Polyethylene or Polypropylene): Polyolefin is the most common material used for shrink film. It is available in two primary types:

Polyethylene (PE) Shrink Film: PE shrink film is often used for packaging food products, consumer goods, and industrial items. It is FDA-approved for direct contact with food and is available in various thicknesses and grades.

Polypropylene (PP) Shrink Film: PP shrink film is known for its clarity and high shrinkage rate. It is often used for packaging items with irregular shapes, such as cosmetics and promotional items.

PVC (Polyvinyl Chloride): PVC shrink film is durable and offers excellent clarity, making it suitable for retail packaging of products like CDs, DVDs, and gift baskets. However, it has become less popular in recent years due to environmental concerns related to chlorine content and recycling challenges.

PETG (Polyethylene Terephthalate Glycol-Modified): PETG shrink film is a clear, high-clarity material with good shrinkage properties. It is commonly used for retail packaging, including beverages, cosmetics, and consumer goods.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)