PLA, PBS, PP Drinks Cup Lid

Description

|

SIZE |

CUP DIAMETER OPEN BETWEEN 80MM-100MM |

|

MATERIAL |

PLA, PBS, PP |

|

MODEL |

STRAIGHT DRINK PRESS TYPE (WITHOUT STOPPER) |

|

SPECIES& APPLICATION |

COLD DRINK LID——SUITABLE FOR DRINKS BELOW 50℃ |

|

HOT DRINK LID——DRINKS BETWEEN 0°C-100℃ |

These lids are crafted with a straight drink press design, offering convenience without the need for a stopper. They are perfect for both cold and hot beverages, with the cold drink lid suitable for temperatures below 50°C and the hot drink lid ideal for temperatures ranging from 0°C to 100°C.

Our drinks cup lids are not only functional but also environmentally conscious, as they are made from sustainable materials that reduce plastic waste. They are the ideal choice for cafes, restaurants, events, and any business looking to provide a convenient and eco-friendly solution for their customers' beverage needs.

Get in Touch With Us

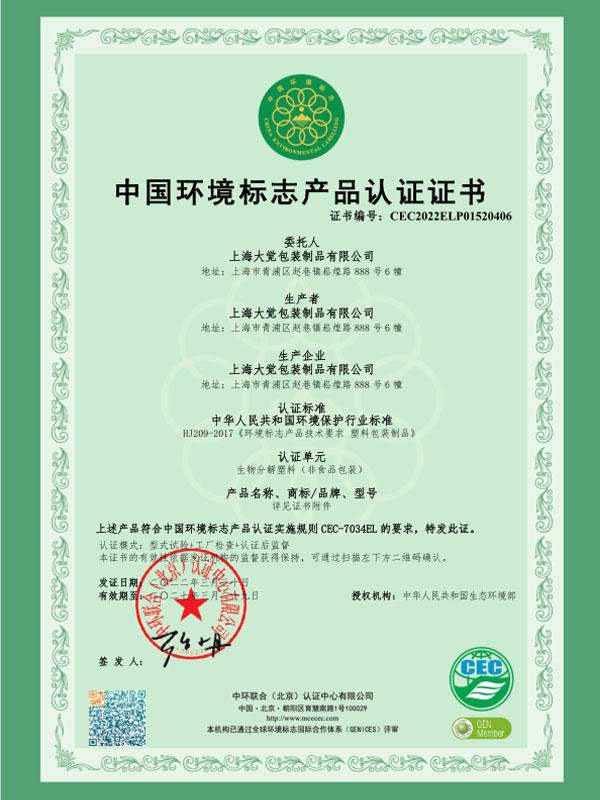

Who Are We?

Dajue (Zhejiang) New Material Technology Co., Ltd.

-

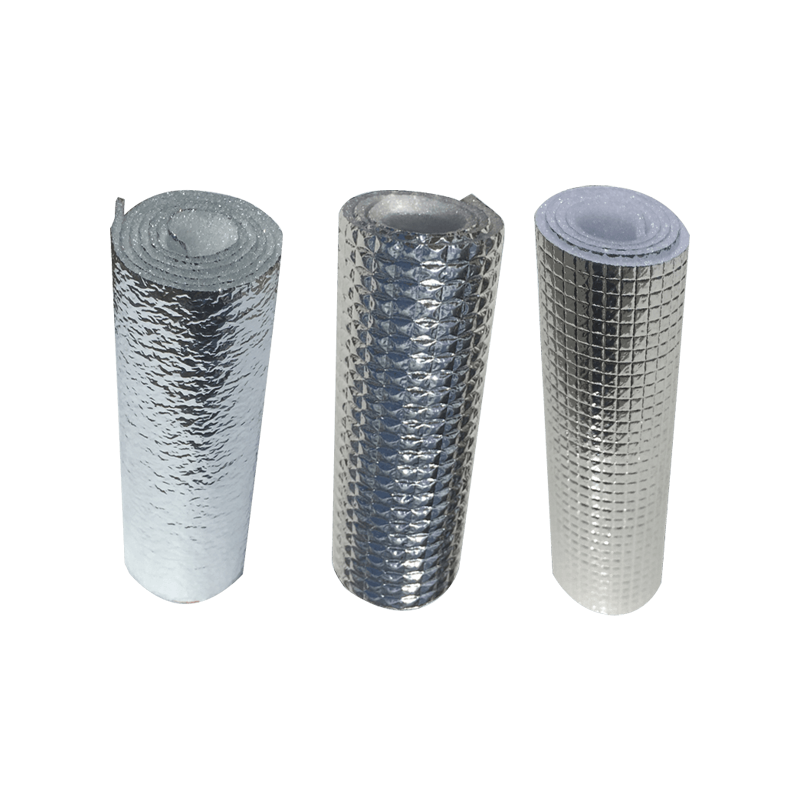

How well does Bubble Film Roll Material protect fragile items?

In the fast-paced world of shipping and logistics, ensuring the safe transportation of fragile items presents a constant challenge...

-

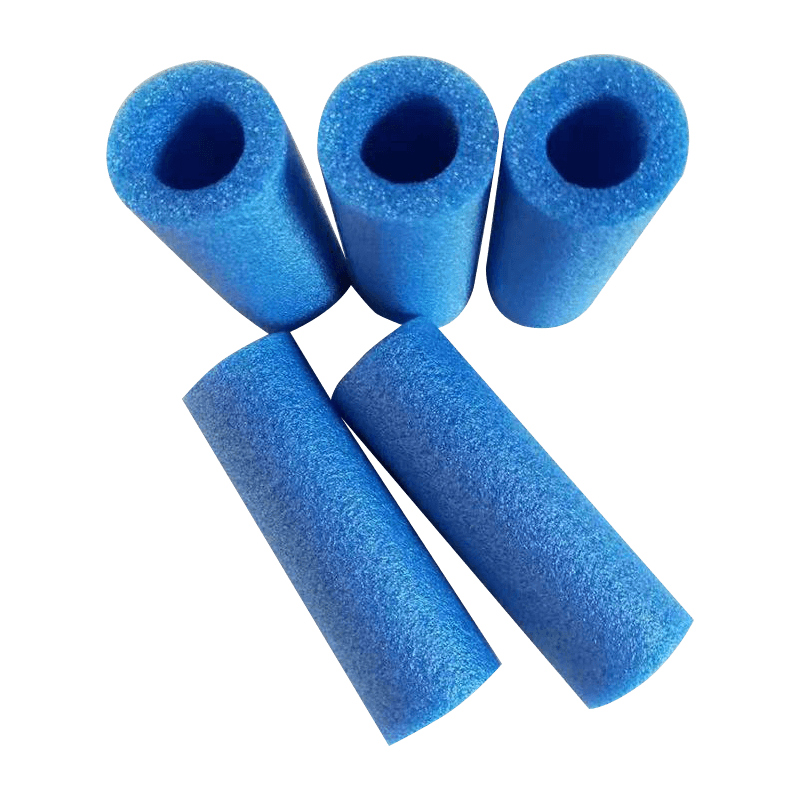

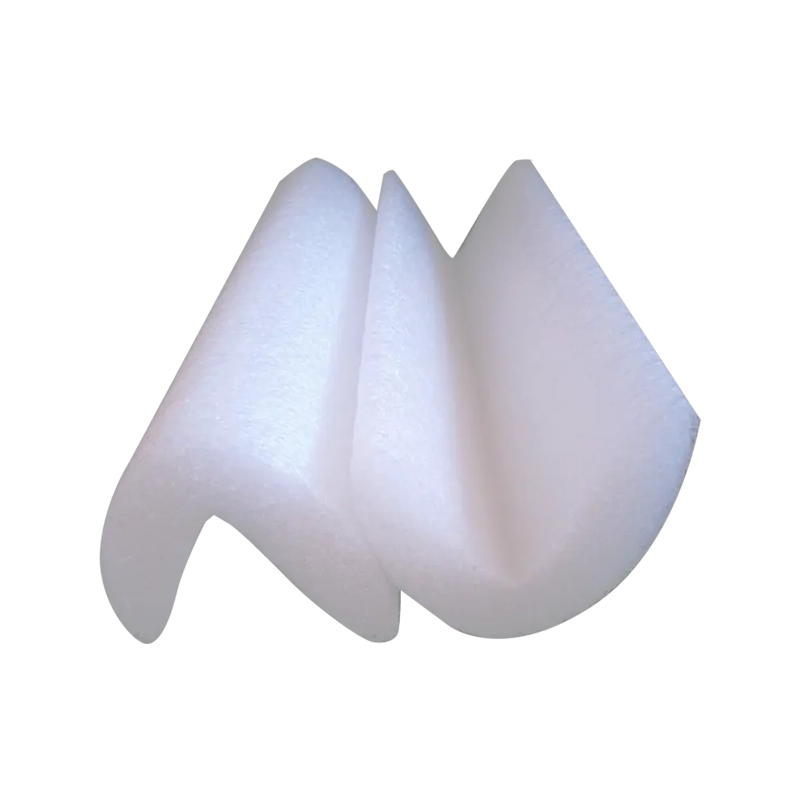

What exactly is EPE foam, and what are its common uses in everyday life?

In the world of packaging, cushioning, and insulation, one material stands out for its exceptional versatility and reliability: EP...

-

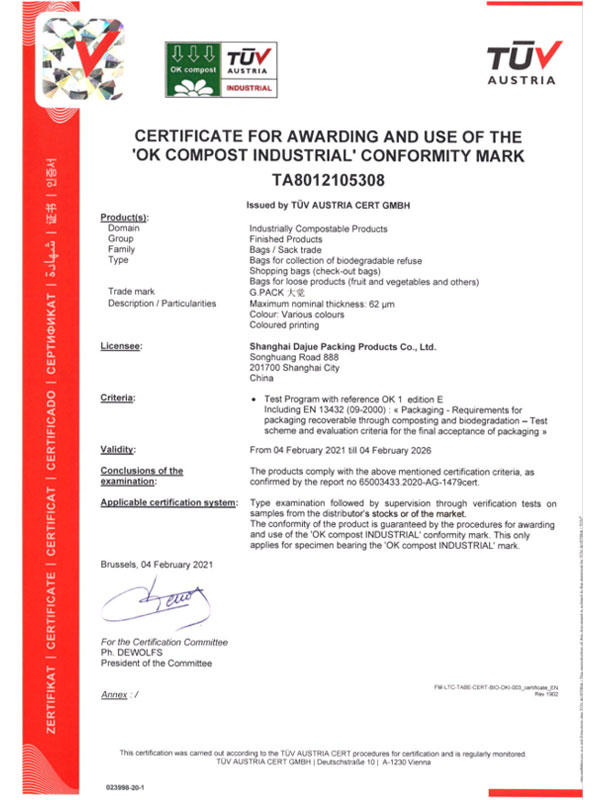

How do the production processes for biodegradable vacuum bags differ from those for traditional plastic bags?

Biodegradable vacuum bags have emerged as a promising alternative to traditional plastic bags. But how exactly do the production p...

-

What are the advantages of using PLAY material compared to other materials for a Biodegradable Breeding Basin?

Innovations in sustainable agriculture have led to the development of novel solutions aimed at minimizing environmental impact whi...

-

How should I dispose of biodegradable bamboo straws?

As environmental consciousness continues to grow, many individuals are opting for eco-friendly alternatives to traditional plastic...

-

Do biodegradable bags cost more than traditional plastic bags?

One of the pivotal debates in the packaging industry revolves around the cost of biodegradable bags compared to traditional plasti...

Product Knowledge

In the ever-evolving landscape of the beverage industry, sustainability has emerged as a cornerstone of innovation. Giants like Starbucks have spearheaded this movement, making impactful decisions that resonate with environmentally conscious consumers. One such initiative is the phase-out of plastic straws across 28,000 stores globally by 2020, a move expected to eliminate over 1 billion straws annually.

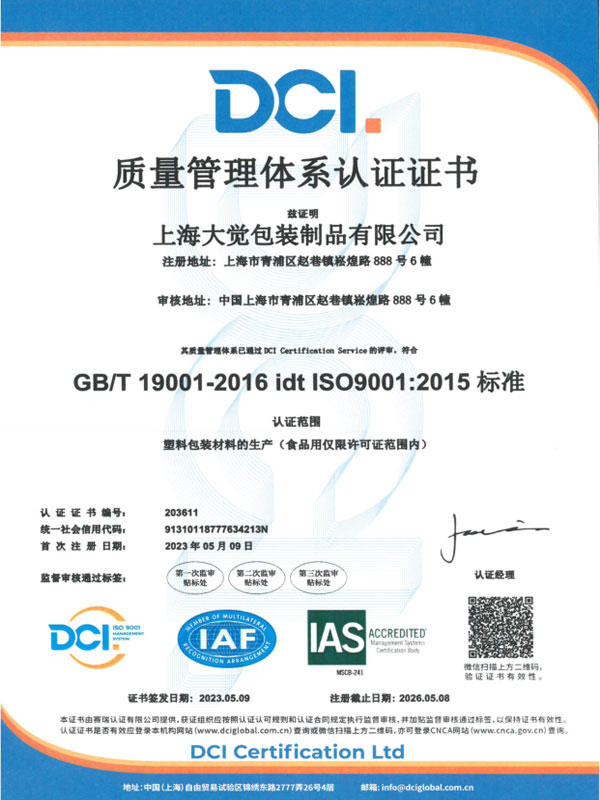

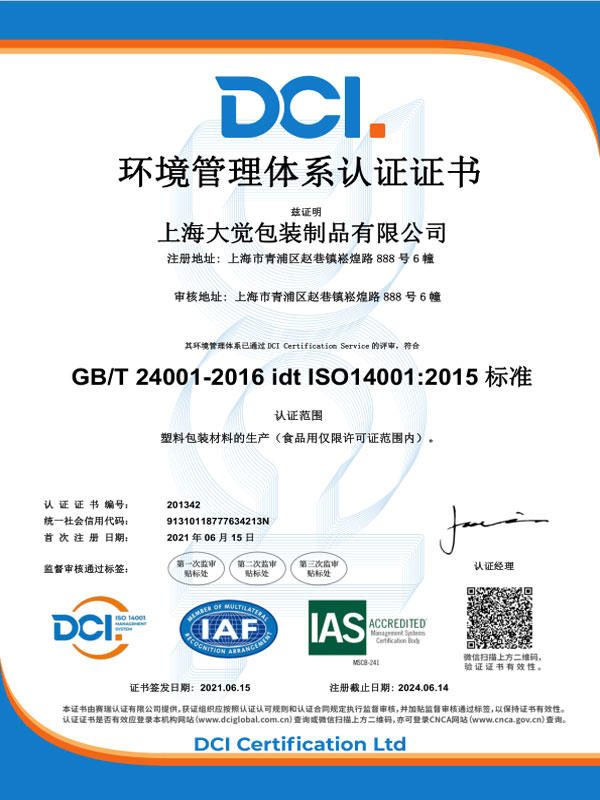

Starbucks' transition extends beyond straws to include the adoption of PLA, PBS, PP drinks cup lids for small-volume beverages, now available in over 8,000 stores across the U.S. and Canada. These lids, crafted from polypropylene, are widely recyclable, marking a significant shift towards sustainable packaging solutions.

Chris Milne, Director of Packaging Purchasing at Starbucks, emphasizes the importance of this shift, stating, "By nature, straws are not recyclable, whereas lids are, so we feel this decision is more sustainable and socially responsible." This strategic move not only reduces environmental impact but also sets a precedent for other industry players to prioritize sustainability.

The impact of these changes is evident in consumer preferences, with cold drink sales soaring from 37% to over 50% by 2017. This surge underscores a growing consumer demand for eco-friendly packaging solutions, reinforcing the notion that sustainability is not just a trend but a fundamental expectation.

As a company specializing in PLA, PBS, PP drinks cup lids, we recognize the pivotal role of sustainable packaging in shaping industry standards. Our products align with this vision of environmental stewardship, offering recyclable and eco-friendly alternatives to conventional packaging materials.

The beverage industry's shift towards sustainability reflects a broader commitment to environmental consciousness. By embracing innovative packaging practices, companies can meet consumer expectations, drive sales, and contribute positively to a greener future.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)