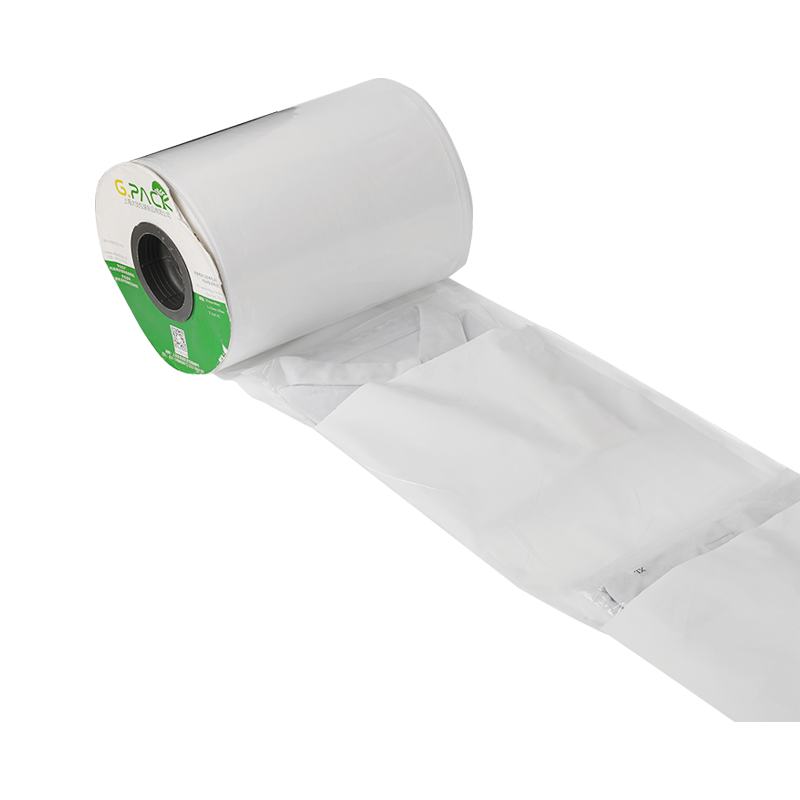

Heat Sealing Film For Lunch Box

Description

|

SIZE |

FOR DIAMETER 20.5CM PLASTIC BOWL |

|

THICKNESS |

2.0S |

|

MODEL |

HOT PRESS ROLL |

|

WEIGHT |

3.2-3.4kg WITH SMALL PAPER CORE |

|

MATERIAL |

PP+PE |

|

APPLICATION |

COLD&HOT FOOD |

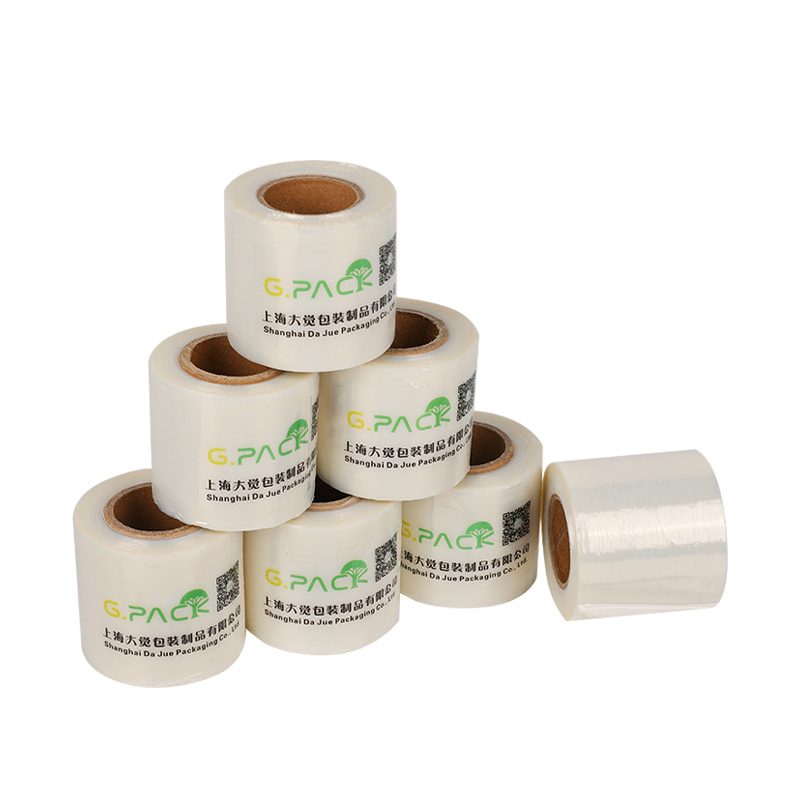

Hot Press Roll Model: Our heat sealing film utilizes a hot press roll model, guaranteeing a tight seal that locks in freshness and flavor, whether you're packaging hot or cold foods.

Premium Material: Made from a blend of high-quality PP (polypropylene) and PE (polyethylene), this film offers exceptional heat resistance, moisture barrier properties, and food-grade safety.

Convenient Weight: Weighing between 3.2kg to 3.4kg per roll with a small paper core, this film is lightweight yet sturdy, making it easy to handle during packaging processes.

Efficient Packaging: The hot press roll model streamlines the packaging process, allowing for faster production and increased efficiency in your operations.

Food-Grade Safety: Rest assured that our film meets strict food safety standards, providing a reliable and secure packaging solution for your business and customers.

Customizable Options: We offer customizable options such as branding, sizing, and packaging quantities to suit your specific business needs and branding requirements.

Get in Touch With Us

Who Are We?

Dajue (Zhejiang) New Material Technology Co., Ltd.

-

How well does Bubble Film Roll Material protect fragile items?

In the fast-paced world of shipping and logistics, ensuring the safe transportation of fragile items presents a constant challenge...

-

What exactly is EPE foam, and what are its common uses in everyday life?

In the world of packaging, cushioning, and insulation, one material stands out for its exceptional versatility and reliability: EP...

-

How do the production processes for biodegradable vacuum bags differ from those for traditional plastic bags?

Biodegradable vacuum bags have emerged as a promising alternative to traditional plastic bags. But how exactly do the production p...

-

What are the advantages of using PLAY material compared to other materials for a Biodegradable Breeding Basin?

Innovations in sustainable agriculture have led to the development of novel solutions aimed at minimizing environmental impact whi...

-

How should I dispose of biodegradable bamboo straws?

As environmental consciousness continues to grow, many individuals are opting for eco-friendly alternatives to traditional plastic...

-

Do biodegradable bags cost more than traditional plastic bags?

One of the pivotal debates in the packaging industry revolves around the cost of biodegradable bags compared to traditional plasti...

Product Knowledge

There are three main methods of heat sealing: manual, automatic and semi-automatic. Each method has unique advantages depending on production needs.

Manual heat sealing is ideal for small food packaging and involves placing a food tray into a heat sealing machine and covering it with plastic wrap. The machine then takes care of the final steps, including sealing and cutting the film. This method effectively meets personalized or customized packaging requirements, providing a tight seal to keep food fresh and safe.

For large-scale food production, automatic heat sealing is a smart choice. Employees load trays of food into the machine, which automatically handles the entire process. This includes wrapping the pallet in plastic film, sealing it securely, precisely cutting the film, and ejecting the heat-sealed container. Automatic heat sealing simplifies production, increases output, and ensures uniform packaging quality, making it ideal for mass production scenarios.

Semi-automatic heat sealing sits somewhere between manual and automated methods, providing a balanced approach. Employees load trays of food into the machine, which then wraps them in plastic wrap. Then, the employee puts the sheet down and the machine starts automatically sealing and cutting the film. This method combines the advantages of automation with some manual control, making it suitable for medium-sized production batches that require customization or specific processing.

Choosing the right heat sealing method depends on a variety of factors, such as throughput, customization needs, and required efficiency. For small runs or custom packaging, manual heat sealing offers flexibility and precision. Automated heat sealing, on the other hand, excels in large-scale production environments, optimizing speed and consistency. Semi-automatic heat sealing, meanwhile, strikes a balance between automation and manual intervention and is suitable for medium-sized production runs with specific requirements.

Our heat sealing film for lunch box is specially designed for lunch boxes or takeaway containers, giving you the flexibility to choose how to use it based on your needs.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)